Film BIO

This is our new "Green" product line for BIODEGRADABLE or COMPOSTABLE flexible packaging. It's “OK Compost” and "OK Compost Home" certified with thick up to 110µm and are specifically conceived for the Food industries.

The true asset of these products is that the raw material used is derived from renewable sources and biobased and contains polylactic acid (PLA) and polybutylene succinate (PBS/PBSA). Over the last years the fields in wich it is possible to effectively use BIO films have increased sharply. Some example taken from our portfolio are:

- Films for frozen food;

- Films for lamination with paper;

- Shrink films;

- Films for thermoforming;

- Films for food packaging

- Films for tissue.

Monomaterial Film

Nowadays most films used in various sectors, like the F&B and the pharmaceutical industry, are hard to recycle. As a matter of fact, flexible packaging is obtained by coupling films made of different polymers, each with its specific functional characteristics. Often, at the end of their lifecycle, as the different polymers cannot be separated, the only possible solution is incineration or landfilling.

A feasible and cutting edge alternative are our range of monomaterial films, a sustainable solution that can replace multimaterial bonded films with films made of polymers of the same group (PE).

The issue of environmental protection in increasingly at the center of attention in Italy and in the world, for this reason we've developed monomaterial films that guarantee a lower environmental impact thanks to greater ease of recycling of the monomaterial structure.

Monomaterial packaging are a new class of products that is constantly evolving and can be used successfully in more and more applications. Currently, there are three main groups:

Recycled-material Film

A series of film that represents the ideal example of circular economy, an environmental-friendly and effective solution.

Jolly Plastic’s films from recycled materials contain up to 50% recycled post-consumption mechanical granule, up to 95% recycled post-consumption chemical granule and up to 90% granule from our own industrial production. All films are ISCC Plus certified and are safe for food contact.

In order to be approved, the optical, physical and chemical characteristics of the film were tested. The possible applications range from the food sector to single-use packaging in the tissue industry.

Our regenerated film portfolio includes three solutions, each having its specific functional characteristics:

RI – Films from post industrial recycling

The acronym RI identifies film containing recycled material from in-house industrial production.

Jolly Plastic selects, separates and regenerates all waste material through a process that is tracked and monitored. Since 2021 the in-house regeneration department has been BRC-certified. Moreover TUV approved our regenerated material for food contact. We can therefore use regenerated materials in food sector packaging.

RC – Films from post-consumer waste chemically recycled

It is our last innovation in waste regeneration, a cutting-edge circular-economy solution in the packaging industry. A selection of household waste undergoes chemical pyrolysis and new virgin materials are obtained! New polymers with excellent chemical-physical properties that are approved for food contact. Thanks to this solution we can replicate the characteristics of many of our standard products while adding different quantities of this type of recycled material.

RM – Films from post-consumer waste mechanically recycled

This material is obtained through the traditional mechanical regeneration of materials from household plastic waste that was carefully selected. This type of regenerated material is not approved for food contact. It can be used to produce film for industrial applications or secondary packaging.

Printing and Lamination

By "Printing and lamination" it is meant the process to join two or more materials so that they adhere to each other creating a single sheet. The goal is to combine materials in order to create supports with the desired specific properties.

The films in our LP range are the core of our production. Over the last 15 years, our films for printing and lamination were constantly updated and renewed in relation to the evolution of raw material performances, the evolution of converting technologies and the increasingly high performances required by final users.

The LP range cover all the applications currently demanded by the market:

- Direct printing

- Flow-pack

- FFS

- Top lidding

- Thermoforming.

The characteristics of each film in this range are calibrated in terms of mechanical resistance, hot-tack and seal strength, COF, flatness and thickness tolerance.

Spreading

By "Spreading" (Coating) it is meant the process to cover a polyethylene substrate with adhesives to enhance and change its physical properties as well as its protection and adhesion ones.

Thermal lamination

By Thermal Lamination we mean the process by which two layers adhere simply as a result of temperature and pressure without the use of other substances or solvent-based adhesion promoters.

Our TL Series, with a high content of EVA, adheres on PET sheets and many other substrates. It is available also with a functional barrier layer of varying thickness, which is ideal for thermoforming:

- TL420: medium adhesion, suitable for separation processes at the recycling stage;

- TL428: high adhesion with a sealing external side;

- TL428-25: high adhesion with an external side peelable to PET.

The TL Series includes both transparent and coloured films, with a thickness range of up to 27 microns.

Labeling

By "Labeling" it is meant the process to put a plastic film identification label on products and packages.

Easy-opening peelable films

Our peelable films for tray lidding and easy-opening packaging are designed to adhere on several surfaces with calibrated peeling forces.

They ensure usability as well as safety and excellent sealing tightness.

The range includes three different adhesion mechanisms based on the desired application: adhesive peeling, cohesive peeling, internal delamination peeling (Burst Peel).

Our solutions are targeted and reliable and designed to adhere to PE, PP, PS, PET, PVC, Aluminium, glass and paper.

The peelable films in the LPEEL series

LPEEL 15: universal peelable film

LPEEL 25: peelable film to PE and itself

LPEEL 30: peelable film to PP

LPEEL 35: peelable film to PP

LPEEL 45: peelable film to A-PET

LPEEL 50: peelable film to Aluminium

LPEEL 55: peelable film to Paper

LPEEL 65: universal peelable film

LPEEL30-R: peelable film on PP, suitable for retort

SPEEL 30: Burst Peel on PP.

Barrier, anti-fog and UV-absorber properties available for all films.

Medical secondary packaging

Our films for the medical field are conceived to meet all the requirements of secondary packaging for medical items. The medical field, by definition, is highly demanding and requires challenging technological solutions.

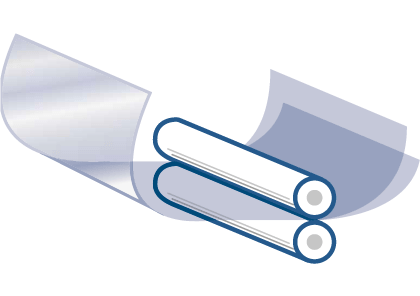

Nine-layer barrier film

A complete range of barrier films with up to 9 layers suitable for different food, medical and technical packaging solutions with excellent oxygen, gas and aroma barrier properties. Upon request we provide films peelable to PP, PS and PET or with anti-fog and UV-block properties.

Our portfolio currently includes:

- single-material PE barrier film, suitable for single-film applications on vertical flow-pack machines and tray lidding;

- PE and/or PP barrier film for lamination suitable for applications on vertical and horizontal flow-pack machines and tray lidding;

- thermoformable barrier film for the bottom part of vacuum and MAP food packaging (flat bread, cold cuts, cheese);

- barrier film for thermal lamination.

Metallization

By "Metallization" it is meant the process to put a very thin layer of aluminum on a surface for aesthetic or functional purposes (barrier properties against oxygen, light, flavorings).

Call us!